While engaging in the improvement of the countryside, it is impossible to do without such a remarkable material as paving slabs.

This is a great solution, tested for years. The coatings are durable, beautiful and durable. Variety of assortment allows you to choose the right kind, which harmonizes with the design of the facade of the house or perfectly fits into the landscape landscape. Yes, and the laying of paving slabs can be performed without the involvement of specialists. With this question it is quite possible to cope independently, especially if you know which side to approach it.

Types of paving slabs

Paving slab is an easy to lay and easy-to-maintain material used to cover areas, approaches to houses, pedestrian paths. In our life tiles came in the 70 years and, despite not the highest strength, immediately became a popular material for upgrading not only city streets, but also suburban areas. Over time, the material evolved, and today, thanks to new production technologies, has become noticeably more practical and more durable in operation, which stimulated the increase in its use.

Sidewalk tile is ideal for upgrading a suburban area

Laying tiles is done in three main ways:

1. Vibration.

2. Vibrocompression.

3. Hyper pressing.

Vibrolite tiles differ from the rest in that they use plastic compounds in the technology of its production. It has high decorative. Such paving slabs are perceived as a wooden or stone covering. The main area of use is individual construction: the material is lined with garden paths and the adjacent space.

Vibrating sidewalk tile

Vibropressed tiles have a rough surface and a strict geometry. It can be found in covering areas, roads, pavements, public places. The laying by own hands of a tile made on this technology is rare. This is work for specialists.

Sidewalk tiles vibropressed

Hyper-pressed tiles are produced using a similar technology. It, as well as vibropressed, is strong and ready to withstand serious loads.

Hyperpressed sidewalk tiles can withstand serious loads

Classify the tile can and on the material of manufacture. For its production use:

- concrete;

- clay;

- a natural stone.

How concrete concrete tiles look like, you probably know – it is the streets that bridge it.

Concrete paving slabs

Clay sidewalk tiles in something similar to roofing tiles: it is also distinguished by high decorativeness. Often manufacturers add granite chips or other astringent materials to the coating that increase the strength of the coating. In addition to the diversity of the color range, the material pleases with a large choice of the shape of the elements.

Clay tile is distinguished by a variety of color series

If you intend to lay paving slabs with your own hands, it will be superfluous to know and gradation of the material by thickness: this will help to avoid unnecessary waste. Pave paths in the garden is quite possible with 20 mm tiles. In principle, it can be used wherever serious loads are not expected, such as driving cars. The territory of the yard is best laid out with elements 40 or 45 mm thick. The thickest tile – 60 mm – the prerogative of the lively trails.

The use of paving slabs with different thicknesses

Advantages and disadvantages of material

The advantages of paving slabs include such properties:

1. Resistance to temperature fluctuations.

This makes it possible to apply it in the landscape design of territories located in different climatic zones.

2. Resistance to ultraviolet.

The cobbled surface does not melt in the sun, like an asphalt surface.

3. Ecological compatibility.

In production, natural materials are used, so that tiling does not harm either the health of people or the environment.

Sidewalk tile is resistant to temperature fluctuations

Granite tiles, in addition to the above, will not allow the rise of groundwater, its pattern will not fade and fade with time. Granite tiles are eternal. It can be removed and moved again. The only thing that prevents its universal application is cost. It is really high, and not everyone is ready to afford such a luxury. However, if you compare the regular expenses for the reconstruction of concrete tiles, then you can think about this alternative.

Granite tiles are eternal

Of the shortcomings noted:

1. Uneven thickness of the coating as a result of a violation of technology when laying the tiles with your own hands.

2. High trauma risk in the winter season. With the onset of frost tile tracks can be very slippery.

Tile laying: preparation for the process

At the preparatory stage, calculate what area is required to lay out, and get acquainted with the technical and operational characteristics of the available samples. Consultants of shopping centers can provide a full consultation on a certain type. Before making an order, make sure that the interpretation you have chosen is strong enough for the mission assigned to it and will safely withstand the weight of the car or person. If the laying of paving slabs is done by oneself, one should also think about the choice of the shape of the elements, especially if they are to be pruned when fitting in place. Since tiles are planned for tracks and grounds near the house, that is, places for walking, the priority should be species with a well-rough surface.

Laying of paving slabs: tools and consumables

Of the supplies, in addition to the tile itself, it will be necessary to purchase sand in large quantities, cement and curbs. From the instruments prepare:

- rubber hammer;

- pegs;

- strong thread;

- Master OK;

- ramming;

- level;

- broom;

- buckets;

- two pieces of an inch steel pipe;

- Bulgar with a nozzle for work on concrete;

- long rule.

Tools for laying paving slabs

For the convenience of laying the tiles you will need your own work clothes and knee pads.

Variants of substrates for paving slabs

“Whichever method of laying the tiles you choose, prepare the ground first”

First of all, we prepare the base and select the composition for the forged layer. The substrate for the tile can be:

- sand cushion;

Sandbag laying

- cement-sand mortar;

Laying on cement-sand mortar

- cement-sand mixture.

Laying on a cement-sand mixture

Whichever method of laying the tiles you choose, first prepare the base. In principle, you can put it on the grass, but then the zone is leveled by piling up rubble. The finished area is covered with a thick layer of sand and is rammed. To simplify the task, the tamping is replaced by an abundant moistening of the sand. It is poured from the hose, through the scattering nozzle. Sidewalk tiles laid directly on top of wet sand. You can not call such a method thorough, but it is quite acceptable for paving garden paths. On such paths there will not be puddles. Water can easily go through the sand.

The paving slab is laid on wet sand

The variant with cement-sand cushion from dry mix is not less simple in realization, but it is more practical in business. The mixture is prepared in a proportion of 1: 5, where the first figure is a portion of cement, and the second is sand. The composition is scattered on the site evenly, but watered after laying the tiles.

Tile on the cement-sand cushion is watered after laying

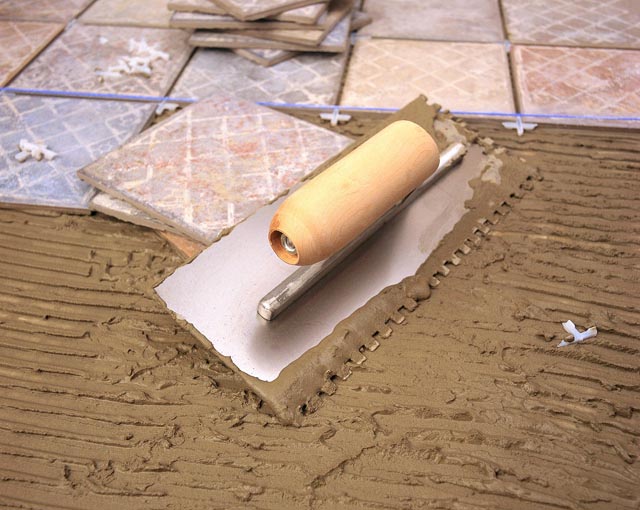

The most practical way is to fix the elements of paving cement-sand mortar. This is the most time-consuming option, as the composition will take a lot and manually kneading it will be tedious. It is advisable to have a concrete mixer handy. The ratio of the components is similar to the previous case. Put the mortar on the ground with a trowel. The layer of the pillow should be about 4 cm. The tile is immersed with a rubber mallet.

Practical way of laying on cement-sand mortar

Stages of laying paving slabs with their own hands

Work begins with the removal of the upper soil layer. The site is leveled and provides it with a uniform slight slope directed towards the street. The process is laborious, but necessary. By biasing, you will ensure the outflow of rainwater from the yard and extend the life of your paving slab. If you do everything according to the rules, then the street level will become the zero point. If you skip this step, you will have to attend to the arrangement of gutters for gutters or rainstorms.

Alignment of the site for laying tiles

Now you need to break the work area into sectors. This is done by pegs and thread. The first two are hammered along the zero line. The horizontal nature of the knotted yarn is checked by level. The latter, correctly applied to the bottom edge. Further pegs are hammered under the control of height, with deducing a corner of a slope of stacking of a tile. All pegs are also connected by a strong thread. As a result of efforts, a rectangle or other figure will be drawn (it all depends on the planned form of the site) within which the main works will be conducted. Now you should bring all the curbs to the specified height.

Layout for laying paving slabs

Prepared for laying paving slabs the area is leveled with small gravel, screening or sand, abundantly watered and compacted. Seal is carried out with a vibration plate or other suitable tools.

The site is leveled with small gravel

The next step is to break up the existing territory into strips and to believe the level of the site relative to the markup. Where the thread hangs too low, remove the excess substrate, in the same pits, it is poured on the contrary. In places where soil is poured, tamping is carried out. The tool can be made independently. The paw of the crane will fit if it is welded to the handle. If the task is correctly performed, the thread will be placed above the ground on two heights of pavement tiles laid. Special accuracy is not needed here, so you can orient yourself to the eye.

With the preparation process over – go to the tiling. Consider the course of work when using a cement-sand mixture.

Under the two parallel threads, bounding the working part, pipes are laid. They must be under them with a gap of a centimeter. The finished mixture is introduced into the designated area of the site and leveled. Now you need to put the pipes on the rule and stretch on all surfaces. Thus it is easy to determine where the lack of underfill. Surplus will be removed automatically.

Preparation of the basis for the tile

Further, the tiles are inspected for defects. The surface of some specimens may have bulges (they are called turtles), concavities (plates) and disproportional curvatures (propellers). The whole marriage is best taken away. Laying pavement tiles of this quality is made only as a last resort.

The hardest part is laying out the first tile row. He will set the tone for the rest of the masonry. Having put the first element, carefully adjust it along the planes and axes of the marking. Tap it with a rubber mallet and drown it in the pillow to the boundaries of the markup. Also, follow the details. You have to do the work “on your own”, then you will move forward, not falling into the substrate, but stepping on the already laid out and fitted surface.

Laying the first row

If, when laying the tiles with their own hands, there are obstacles, for example, sewer hatches, then they should be covered with whole elements, leaving the fit for later.

Tiling with sewer hatch

Every working day must be completed by the process of promiscuity. This is done using all the same cement and sand. Mix them in a certain proportion, abundantly sprinkle with the composition of the finished piece of paving slabs and mark it with a broom. The mixture will fill the gaps formed.

Paving of paving slabs

Council number 1. When working with a colored tile after sweeping with a cement-sand composition, a white coating may appear. Often, the reason for this is the quality of the material. Adequate manufacturers usually specify this nuance of laying tiles in the recommendations to the product. In order not to risk, exclude the use of cement and mark the surface with clean sand.

Spot the surface with clean sand

Tip # 2. When defects are formed, the masonry is corrected with a solution of cement and sand mixed 1: 2.

Laying paving slabs is completed by framing the area with curbs. Along the edge, a small trench is dripped, using a trowel or a small spatula. The depth is determined by the height of the fit of the enclosing element. After installing the sections, the borders are fixed with a concentrated concrete solution. Along the fence, there are certainly areas that need to be trimmed with tiles. Before putting the parts into place, it is necessary to re-compact the soil in the reconstructed areas, since during the digging of the trenches it could be somewhat crumbled. If necessary, pour the required amount of counterfeit material.

Framing a plot with curbs

In the places where the sites are adjacent to the gate or gate when laying the sidewalk tile with their own hands, I need to take not dry compositions, but a good fastening solution, because here the load on it will be the most significant.

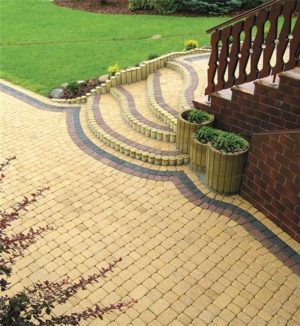

Sidewalk tiles in the décor of a country house yard

You can lay tiles in several ways. Beginners should work on a simplified scheme, when two colors alternate in a certain order. More advanced in the construction industry can try to create real masterpieces, laying out of the tiles intricate patterns. Pave a yard or garden alleys can be a material of ordinary rectangular shape. Despite the mold simplicity, laying paving slabs can be successful in color combination. Of the multi-colored elements, it’s easy to put an interesting composition. For more original compositions it is better to choose a tile in a figured design.

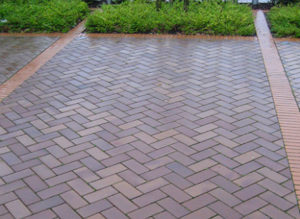

Fur-tree

This is one of the most accessible ways of art tiling your own hands. The pattern is obtained by paving the elements at the selected angle. The latter can be equal to 45o or 90o. The variants of the Christmas tree are also referred to as a braid. In this case, the tile is alternated in longitudinal and transverse packing.

Sidewalk tile, laid herringbone

Chaotic variant

Random plitkosmes also will look very good in the design of the garden. Creating a chaotic pattern is also not difficult. It is enough to purchase consumables in a variety of shapes and colors, and simply lay out the available items in an arbitrary order. The result is usually very impressive.

Chaotic way of laying

Chess way

Chess tile laying is a variant of the courtyard decor, which even a child can realize. It’s simple, but it’s effective enough. For work it is possible to take both a tile of the square form, and rectangular, only in the latter case for creation of cells elements should be stacked in pairs.

Stacking of tiles in staggered order

Snail

A circular pattern of laying is the top of the building and “bridge” skill. In this way, you can beautifully decorate the relaxation corner in the garden or the area in front of the house. Creative individuals in the creation of circular patterns manage to achieve delicious results. Sidewalk tiles, laid by a specialist, will look great both in the usual foreshortening, and from the height.

Circular laying of paving slabs

Combination with lawn

In the power of yard areas, especially designed for recreation, it is worth combining the sites of laying paving slabs with green lawns. This technique will help to add aesthetic areas and not to break the delicate balance between civilization and nature.

Combination of paving slabs and lawns

Care of the paving slab

“Clean the ice can be special reagents suitable for the treatment of paving slabs”

Like any surface, tile tracks also need some care. If in summer the main enemies of paved areas are dust and dirt, which are easily swept out and washed away, then in winter it becomes much more difficult to look after them. Ice-covered and submerged tracks can not be cleaned with brute force. Do not force them to ice. Snow is removed with a plastic or wooden snow shovel.

Cleaning paving slabs in winter

Remove naled can be special reagents suitable for the treatment of paving slabs. Salt in this business is a bad helper. It corrodes the decorative layer of the material and leads to a loss of color. You can take care of your cobbled areas ahead of time, and treat the tiling with a hydrophobic. The composition forms a protective film, which will not allow ice to adhere to it. As a result, the ice crust itself will depart from the site and it will only be scraped aside. Also, similar solutions prevent the appearance of mildew and bacterial lesions on the tile, and also prevent the formation of efflorescence.

Hydrophobizer for paving tiles will create a protective film

Conclusion

Sidewalk tile – a practical material, inexpensive and opening up space for creativity. It can be very successfully used in the decoration of the territory of the countryside, using as an independent decorating element or logically adding paving to the design composition. Make your yard beautiful easy, the main thing is to have the desire to work on it with your own hands.

Photogallery – paving slabs

Video

Author: Mikhail Bond

05.05.2023 @ 18:31

erman:

Beim Verbessern des ländlichen Raums ist es unmöglich, auf solch bemerkenswertes Material wie Pflastersteine zu verzichten. Dies ist eine großartige Lösung, die seit Jahren getestet wird. Die Beläge sind langlebig, schön und robust. Die Vielfalt des Sortiments ermöglicht es Ihnen, die richtige Art auszuwählen, die sich harmonisch in das Design der Fassade des Hauses einfügt oder perfekt in die Landschaft passt. Ja, und das Verlegen von Pflastersteinen kann ohne die Beteiligung von Spezialisten durchgeführt werden. Mit dieser Frage kann man durchaus selbst zurechtkommen, insbesondere wenn man weiß, von welcher Seite man sie angehen muss.

Pflastersteine sind ein leicht zu verlegendes und leicht zu pflegendes Material, das zur Abdeckung von Flächen, Zugängen zu Häusern und Fußgängerwegen verwendet wird. In unserem Leben kamen Fliesen in den 70er Jahren und wurden trotz nicht höchster Festigkeit sofort zu einem beliebten Material für die Modernisierung nicht nur von Stadtstraßen, sondern auch von Vorortgebieten. Im Laufe der Zeit hat sich das Material weiterentwickelt und ist heute dank neuer Produktionsverfahren deutlich praktischer und langlebiger im Betrieb geworden, was zu einer Zunahme seines Einsatzes geführt hat.

Gehwegplatten eignen sich ideal zur Modernisierung eines Vorortgebiets. Das Verlegen von Fliesen erfolgt auf drei Hauptarten: 1. Vibration. 2. Vibrokompression. 3. Hyperpressung. Vibrolite-Fliesen unterscheiden sich von den anderen dadurch, dass bei der Herstellung Kunststoffverbindungen verwendet werden. Es hat eine hohe Dekorativität. Solche Pflastersteine werden als Holz- oder Steinbelag wahrgenommen. Der Hauptanwendungsbereich ist der individuelle Bau: Das Material wird mit Gartenwegen und dem angrenzenden Raum ausgekleidet.

Vibropress-Fliesen haben eine raue Oberfläche und eine strenge Geometrie. Es kann in Bereichen, Straßen,