And the owners and guests of the country house will be pleased to observe the good interior decoration. High quality materials and good finishing will only positively affect the mood of people. And the use of vagonki in the interior of the country house will decorate any dacha premises.

Lining is a special thin board, which is used for interior decoration of buildings, as well as for exterior decoration of buildings. It is one of the most popular finishing materials due to high performance properties and a large number of variations of appearance.

Lining for interior decoration of premises

Varieties of lining

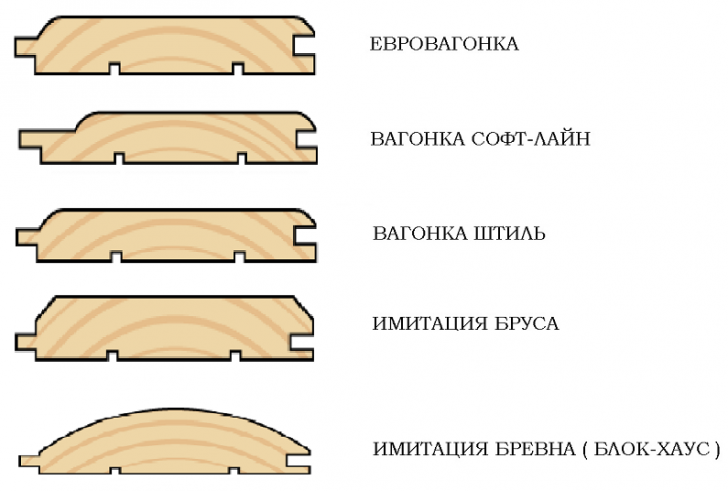

Classification of lining is made on the material from which it was made and its grade. Also, finishing boards are subdivided according to the profile, that is, to its external appearance and method of connection.

- Wooden. This type of finishing boards is made from hardwood or coniferous wood such as ash, aspen, beech, pine and others.

Wooden finishing board

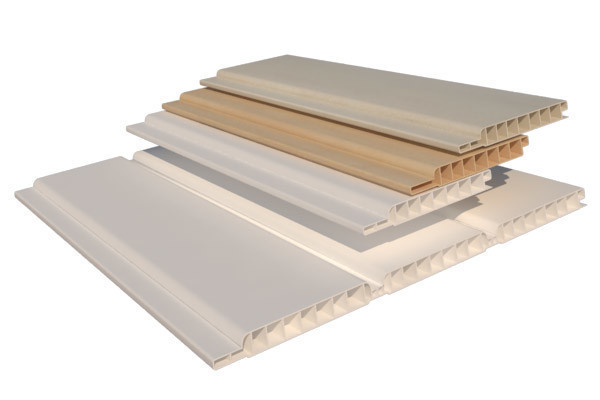

- Plastic. This lining is produced from PVC materials by extrusion. This is the way of giving the object the necessary shape by extrusion at the optimum temperature.

Molded board made of plastic

- From MDF. This type of lining, unlike wood, is not cut out from a full-fledged tree, but is glued from wood chips without the addition of harmful impurities. Thanks to the method of production, it is characterized by a special density.

Board from MDF

- Aluminum. This lining is used exclusively for external cladding. Its advantages are light weight, and also not susceptibility to corrosion from external factors. But low thermal insulation and little protection against physical impact makes it completely unsuitable for indoor use.

Aluminum paneling

Separately it is worth mentioning the classification of wooden dependence on the grade and quality of the material produced.

Top class is denoted as “zero” or “extra”. The lining of this class does not contain the core of the tree, nor any defects in its structure.

Wooden forcing of the highest class

The lowest is the third class, it is also referred to as “C”. In such lining there are only blind cracks, as a maximum of two knots that do not fall out, resin sacks, stains of excellent color and mechanical damage.

Wooden lining of lower class

The profile determines the appearance of the boards, as well as the connectors for their connection. Bags of each type are produced in variations with different profiles. The most popular at the moment are “standard”, “Soft-line”, “blockhouse” and “American”. They differ in the butt component, the presence or absence of an air gap and many other characteristics.

Classification of wooden lining

Advantages and properties

The lining from each material has its own set of distinctive features and advantages. And, accordingly, are used for different facing works, in accordance with their characteristics

Wooden lining

These boards are made from whole kinds of wood, which is distinguished by their ecological compatibility, respectively, complete safety for human health. It is treated with special compounds that prevent water from seeping into the lining. This makes it resistant to decay and increases the overall durability of the material. Plus, it provides a good heat preservation.

Decorating the room with wooden lining is completely safe for the person

Wooden facing boards have a pleasant slight smell of trees, which will have a calming effect on those who will feel it.

It is often called the Eurocup, for full compliance with European quality standards.

Wooden Lining

It has a pleasant and natural appearance. Due to the special processing of wooden lining, it is possible to impart the external properties of any wood color. The use of such a lining in the interior of a country house will make its appearance more “expensive” and attractive.

Finishing the room painted with wooden lining

Perhaps its main drawbacks will be a high price for boards made of quality wood “extra”, as well as the need for regular color updates and special composition on it.

Plastic lining

This lining is different from wood by its unnatural origin. Nevertheless, the PVC material is absolutely harmless to human health. Inside it is hollow, which makes it not so reliable, but much easier.

Room decoration with PVC lining

The material from which the lining is made is moisture resistant, without the need for additional processing. But, it is not suitable for installation in rooms with high temperature conditions. In such rooms, the plastic will begin to melt over time.

PVC lining is resistant to high humidity

Sound insulation and heat preservation at the same level as the wooden version, thanks to the air layer inside the PVC.

The price for such a lining is much lower due to non-natural materials of production. Plus, everything does not require as much attention as the wooden

Board from MDF

This type of finishing boards is an intermediate option between PVC and wooden. The material is environmentally friendly, because it consists of wood shavings. It has an increased density of structure, accordingly, the water does not penetrate inside, it does not require special care, it is enough to simply wipe with a damp cloth. Also worthy of note is the pleasing appearance of the boards.

Decorating the living room with a lining of MDF

Aluminum paneling is not considered, as it is not completely suitable for the internal lining of the house.

For the price, this is something between a plastic lining and a wooden one.

A common advantage of these finishing boards is that they can hide the wiring without any problems. Also, installation of the lining with proper approach will not make any difficulties. A variety of external types will fit into the interior of any country house.

Choice of lining

The choice of lining must first of all be based on the customer’s budget, his personal preferences, the style of decorating the house, and also the specific place of installation. For example, if the amount of funds is limited, instead of buying wooden finishing boards of the grade “C”, you can prefer a cheaper plastic analog. For bathrooms or baths, you should choose a lining from a material that is more resistant to moisture. Thanks to the right choice, the overall service life will increase.

Finishing of bathroom plastic clapboard

The higher the quality of the lining material, the greater its price. Choosing MFD boards instead of full-value wooden products will save you, with a slight loss of quality, but with a presentable appearance.

Finishing MDF battens more economical wooden

Low-quality lining should be finished all the extensions in the country, not intended for living there, because for them special properties of the content is not required. Or auxiliary rooms inside the house.

Finishing the balcony with a low-quality lining

By analogy with these situations, and should make a choice, the use of lining in the interior of a country house corresponding to the specified characteristics will make it as true as possible.

Installation

To make the lining an excellent decoration for a country house, it provided good sound and heat insulation, looked presentable, without curvature and cracks it must be correctly installed. For greater efficiency, the installation can be combined with general repairs, in particular cable laying. The board will serve as an excellent insulation for the wiring, making it completely invisible, but at the same time protected from mechanical influences.

Preparatory stage

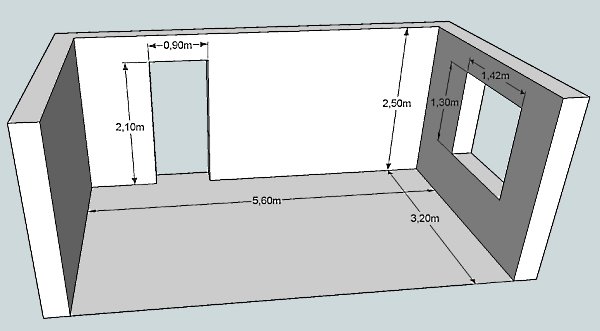

The installation of the lining starts from the moment of calculations and selection. It is necessary to find out the quantity, size, as well as the material of the boards needed for the cladding, and then order them.

Measurements for calculating the area of walls

After that, it is necessary to clean the plane on which the lining will be placed, from dust, dirt, remnants of wallpaper, paint and other debris. Next, you need to assemble, install and fasten the crate over the wall, floor or ceiling. It will be the link between the plane and the facing boards. The cladding will consist of a set of fixed rods, with a step of fifty centimeters. Their position will depend on the future way of installing the lining. If it is planned to be installed vertically, the rails must be installed parallel to the floor. If horizontally, then everything is exactly the opposite.

Wall lining for installation of lining

Most often the crate is made from various lumber, the type of timber. Such racks are easily fastened to the lining, but less reliable than the metal profile. But it differs in the difficulty of the connection.

During the installation of the battens, you should also take care of additional insulation and insulation, as well as hiding the wiring.

Thermal insulation coating

At the fixing of the rods, the preparatory stage ends.

Installation of lining

After installing the crate, it should be treated with an antiseptic agent. Next is the installation of lining. When using wooden facing boards, you must give them at least one day to dry.

The installation of the lining starts from the corner, in the case of a vertical arrangement or from the top or bottom of the room, in the case of a horizontal arrangement.

Installation of the lining starts from the corner

The first board must be attached to the rails of the crate. You can do this simply by hammering a through nail into it or screwing in the bolt. This method is simple, but it makes impossible the subsequent dismantling of the lining without violating its integrity, plus it will spoil its appearance.

Fastening of the lining to the wall with bolts

An alternative option would be the use of Kleimers. This is an element of the fittings, which, thanks to its structure, is easily mounted on the lining profile, with subsequent reliable fastening. And with the possibility of removal without violating the integrity of the facing board. Kleimer is attached to the lining, and after it is screwed to the rail.

Wooden lining with kleymers

Thus, only the first and last board will be fixed. Intermediate will be connected with each other by butt due to the construction of the profile.

If the lining is installed vertically at a distance from the floor, then to maintain it is better to use a pallet. It can be made as a convex rail, which will be held on the crate.

The use of Kleimers will increase the total cost of installing the lining, but will make it “reusable”. That is, during the overhaul it can be removed without any problems, and then returned to the site, or simply transferred to another room. The integrity of the board itself will not be disturbed, nor will its appearance deteriorate.

The fastening of the lining with the Kleimer will allow the decoration to be reusable

Bolts and nails are suitable for a cheaper version of the installation of the lining, but without the possibility of a complete dismantling. But, if you do everything very carefully, then the appearance of the facing board will not suffer.

Fastening of vagonki self-tapping screws

Care

A complete pleasure will be the finish with a lining of MDF. Thanks to the excellent external characteristics and properties of the material, it can be an excellent decoration of a country house. But the main advantage is that you do not have to spend a significant amount of time on it. It is enough to wipe dust occasionally with a damp cloth.

Finishing MDF lining is unpretentious in care

Care for plastic or MDF lining will consist only in the regular wiping it from dust. With wood everything is more complicated.

Over time, the coating composition will come off the board, and the color will also be lost. Accordingly, this should be monitored. Restoring the external qualities of the lining is best with dismantling.

The paint layer of the wooden lining needs special care

The first step is to prepare a place in the room. Its temperature should be approximately equal to room temperature (20 ℃), and humidity is between 50 and 70 percent. Next, you should lay the floor in the room and place the dismantled lining there. Remove from it a layer of varnish and paint, and after processing. Then it should be dyed twice, both times allowing to dry. And after applying the lacquer, allow it to dry out for two days and re-assemble on the lath, first cleaning it, too.

Variations of the use of lining in the interior of a country house

Boards of this type are a universal option for finishing works. They can be universally applied on the territory of a country house. With proper use of lining in the interior of the country house will be a unique combination.

Traditional finishing with wooden lining of a country house

Advice from the master decorator:

Quite an interesting solution will be facing each room of a country house with the help of a lining of different colors. It is desirable that the color range of different, but the number of rooms in contrast. But not in the case of too dark shades, they will produce a depressing impression and it is better to avoid them altogether in the interior of a country house.

Non-standard orientation

The use of lining in the interior of a country house does not have to consist exclusively in installation horizontally or vertically. With a correctly assembled crate of lining boards, you can create various variations of ornaments. For example, the outer perimeter will be square, and inside the lining will go diagonally. Thanks to this approach, combined with the experiments of the color palette, it is possible to turn the interior of a country house into something unique and unique. Such that will please every day both guests and owners.

Ornament with wooden lining on the ceiling

Facing the living room is a very important action, because it will depend on the internal appearance of the house, as well as the impression and mood created. The more pleasant the dwelling will look, the more comfortable it will be. That is why the use of lining in the interior of a country house is so popular

Photo gallery – lining in the interior

Video

Author: Mikhail Bond

05.05.2023 @ 19:29

ng will give it a natural and cozy look. The use of high-quality materials and good finishing in the interior of a country house is essential for creating a comfortable and pleasant atmosphere. Vagonki, or lining, is a popular finishing material due to its high performance properties and a wide range of appearance variations. It can be made from wood, plastic, MDF, or aluminum, each with its own set of advantages and properties. Wooden lining, in particular, is eco-friendly, safe for human health, and provides good heat preservation. It also has a natural and attractive appearance that can make any country house look more expensive and cozy. Overall, the use of vagonki in the interior of a country house is a great choice for those who want to create a beautiful and comfortable living space.