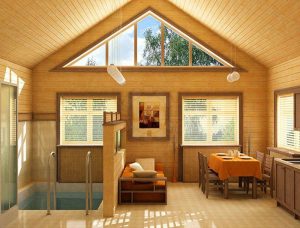

The tree, as a building material, will never come out of our everyday life, the atmosphere in such houses is too good and cozy. The exterior of the felled structure is no less magnificent.

Today it is not difficult for him to give both a modern and a fabulous look. For this, there are many different technologies. But what to do with the walls in a wooden house? Their unusual structure probably requires a special approach, because just stick the wallpaper here will not work? Indeed, without preliminary preparation will not work, and this should be discussed in more detail.

Criterias of choice

The choice of finishing material for interior work in a wooden house will depend on the region in which the facility is located and how it is planned to be operated. If it is planned to spend summer only in the city, then it is quite possible that you would prefer to simply paint, apply a toning solution or varnish the wall surfaces, especially without bothering with their leveling and other gardening works.

The walls of the wooden house, varnished

For a year-round residence, such solutions may not be entirely adequate. We can not ignore the need to create an interior stylistics, where the appearance of the walls plays an important role. In many cases, their surface should be perfectly flat, which is achieved by decorative sheathing.

Types of finishing materials

“Well-proven ash, which is practically not afraid of high humidity, so that products from it can be used in rooms of any functionality, without restrictions, but the coniferous lamellas will heat up when heated, which means that in the kitchen such material is in the finish it is better not to apply “

What can you do today to cover the walls in a wooden house? Designers actively use:

1. Wooden lining.

2. Various panels.

3. Block House.

4. Drywall.

5. Decorative stone.

6. Plastic.

If you focus on wood derivatives, be sure to consider the quality of the wood from which they are made. Well-established ash, which is practically not afraid of high humidity, so that products from it can be used in rooms of any functionality, without restrictions, but the coniferous lamellas will heat up when heated, which means that in the kitchen such material in the finish is better do not apply.

Sheathing of walls in a wooden house with ash

Often the walls carry a weight load. The furniture and decor are fixed on them. This, too, should be taken into account when choosing a material, since it must have an adequate margin of safety for the realization of such design delights. Find out how suitable for interior decoration of a material, you can by getting acquainted with its characteristics.

Wooden lining

Wood – the material is easily processed. It’s easy to cut, plan, grind. The material has a wide palette of shades and a variety of textures. Wood is an excellent muffler and heat insulator. Proper mounting of the skin will allow it to be used for many years.

Sheathing of walls in a wooden house with a lining

The energy of the tree is also pleasant. In a room with such decor there is no place for depression and despondency. The atmosphere in it always stimulates an increase in mood.

At its core, the lining is a regular board with special fastening slots, which allows the elements to be tightly fitted to each other when the wall is clad.

The lining has excellent thermal insulation properties

Looking through the product range, look for models designed for interior work. They will also be presented in different profiles and sizes. Their surface can be either untreated or perfectly smooth, which also makes it easier for the designer to work on creating an interior style.

Types of wall paneling

Getting acquainted with the characteristics, pay attention to the type of wood that went to the manufacture of the vagons that attracted you. This item is mandatory if you are selecting the skin for not well ventilated and dry rooms. For bathroom it is better to choose not derivatives of conifers, but variants from linden, oak, alder.

Sheathing of bathroom with lining of coniferous wood

Wood paneling is extremely popular. It can be found in almost every home and this pattern of finishing material often stops the admirers of individuality. But still, this fact does not detract from the merits of the vagonki, because she:

- practical;

- is universal;

- environmentally friendly;

- is presented in a large species and quality assortment;

- exudes a magnificent aroma.

Wall paneling board is universal and environmentally friendly

The cladding is mounted on a frame structure, assembled from metal profiles or wooden bars. This is the easiest way to hide the unevenness of the bearing surface. Lamels to the crate are attached with clamps or in the old manner – with screws and nails.

Cladding of walls in a wooden house with lining

When choosing a fixing method, consider this nuance. If you have purchased a lining that has not passed chamber drying, the lamellas will gradually lose moisture, that is, dry out, which means that there will always be crevices between them. You can not avoid the process, so you’ll have to:

1. Resign with what is happening.

2. Correct the situation.

Sometimes you need to adjust the skin several times, so before you nail the lining tightly, think about how you will remove it if necessary. Self-cutting can be the optimal solution in this case. They will be easy to unscrew during the reconstruction.

Fixing the battens with self-tapping screws will further disassemble the cladding

You can purchase profiles, in the assembly of which, the cracks from desiccation remain almost invisible. It can be “Softline” or “Standard”.

Evrovagonka

Externally, this material is associated with the usual lining, but its characteristics at times exceed it. In the first place comes such a weighty argument as the German quality. The lining of the lining is well ventilated and has an additional furrow, which functions as a drainage system. This increases not only the life of the skin itself, but also the wooden wall hiding beneath it. Euroanalog will not have problems with deformation of the surface associated with swelling, which makes it the No. 1 material for finishing the bathrooms.

The lining of the walls of the lining is absolutely not subject to deformation

The surface of the lamellas is perfectly even and tactilely pleasing. Products are initially treated with protective compounds, which eliminates the need to do this before assembly, as when working with clapboard of the usual class. The beauty of the wood structure and the uniqueness of its design from such procedures does not suffer.

Drywall casing

Hide construction defects and hide communications will help finish the walls with plasterboard. Behind its sheets there is a place for a heater, and they themselves are quite good heat and soundproofing. The material is able to regulate the microclimate of rooms, absorbing and giving away moisture.

Hypocomposite cover supports microclimate indoors

Its constructional qualities are incredibly attractive. Sheet gipsokarona can be bent, which allows to give the walls and corner joints an arbitrary shape. If you decide to cover the walls in a wooden house with plasterboard, then in parallel protect them from damage by rodents. The secret is that during production, the sheets are soaked with some chemical compounds, which frightens the living creatures.

Sheathing of gypsum cardboard will save the house from rodents

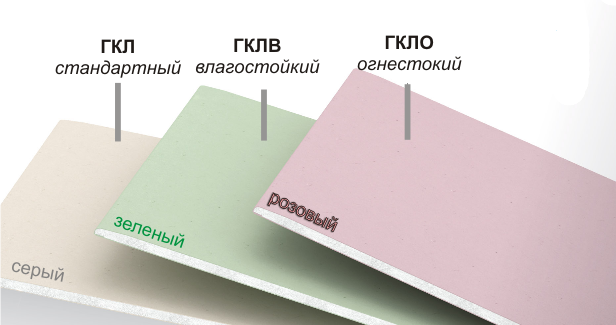

The material is presented in varietal diversity.

In rooms with normal humidity they work with wall plasterboard. In damp premises use a moisture-resistant appearance, and in places with increased temperature and risk of fire – gypsum board with a fireproof coating.

Types of plasterboard for wall covering

Any of the presented species is ecological and has an acceptable price. The large size of the sheets guarantees the speed of mounting the skin. The resulting surface can be painted or used as a base for laying tiles and applying decorative plaster.

Drywall can be painted in any desired color

The technology of installing gypsum plasterboard plating in a country house made of wood is no different from the process of finishing the walls of city apartments. Similarly, the carcass is assembled and the sheathing sheets are fastened in the same way.

Since gypsum is a fragile material, it can only be used in the design of houses where the shrinkage process is already completed. Be sure to leave a gap of several centimeters under the ceiling and near the floor. Wooden walls of the house remain “alive” always. They swell in damp weather and dry out in the heat. Incorrectly made plating will simply tear. Ignore these processes of living at home by installing a floating frame, which is provided by a non-rigid attachment to the wall profiles. Having a reserve of movement, the profiles will be able to keep the drywall in its original position, no matter how the frame has behaved.

The process of plastering the walls of a wooden house with plasterboard

Protect the surface of the skin from the formation of cracks can be, reinforcing all joints and corners reinforcing mesh of polymers.

It is also possible to coat the walls of a wooden house with gypsum plasterboard without assembling the frame. In this case, they will be fastened to slats, bars and glue compounds. Thus, an additional area is won, which is very important for small rooms.

Wall panels in the interior decoration of wooden houses

Decoration of walls inside a country house with special panels allows you to diversify stylistic solutions of interior decor. This is guaranteed by the factual variety of the material.

Wall panels produce:

- from fiberboard;

- MDF;

- bamboo;

- plastic;

- glass;

- skin.

The most popular are fiberboard panels. They came to the interior design not so long ago. The classification of the material is based on species diversity.

Finishing the walls of the house with fiberboard panels

The set racking models have a small width (10-30 cm), a variety of length (from 2.5 m to 6 m) and a thickness (8-2.5 mm), which is very similar to a wooden lining. Association strengthens the presence of a similar scheme of the connection of the spike / groove and the way of fastening the skin to the walls of the wooden house, where staples and clamps are used.

Rack panels

Tiled species are also represented in a dimensional and color variety, which allows you to hide the walls behind real panels or reproduce the most incredible figures in the skin, combining tile panels of different shades and shapes.

Finishing with tiled fibreboard panels

Sheet variants are offered in not less wide dimensional range and their appearance is very similar to that of hardboard. Their surface may have just a single color, and be framed in 3d technique.

Sheet Fiberboard for Walls

Laminated covering of fiberboard panels imitates both the structure of natural materials such as marble, granite, wood, tile, metal, and pleases with fantasy motives. Elements can be covered with bright patterns, ennobled with mirror inserts, picture reproductions, stucco or thematic plots.

Laminated fiberboard panels imitate natural wood

The fiberboard panels are robust. They securely fix the screws, so there will be no problems with fixing the shelves of lamps and other accessories. For all types of wall fiberboard panels, you can select the appropriate accessories and moldings for the decoration of joints and concealment of wall defects.

This includes:

1. Moldings.

2. Corners.

3. Skirting boards.

4. Base planks.

5. Platbands, etc.

With the help of such elements, a uniform interior style is formed, so do not abandon their use.

MDF panels, in view of their water resistance, are most often used in the decoration of bathrooms. The option is cheap, convenient and eco-friendly. Panels of this type are easy to install, have good thermal insulation characteristics, are durable, well washed and have a rather aesthetic decor. You will easily find them in the texture you need.

For plating the bathroom, the MDF panels

Glass panels are often used not as an independent skin, but as inserts. More voluminous areas can be seen in the premises of a specific purpose. They make out a working wall in the kitchen or bathroom. Glass plates can be completely made of colored raw materials or have only decorated with corrugation, photo printing, tonic or surface drawings.

The kitchen apron is decorated with glass panels

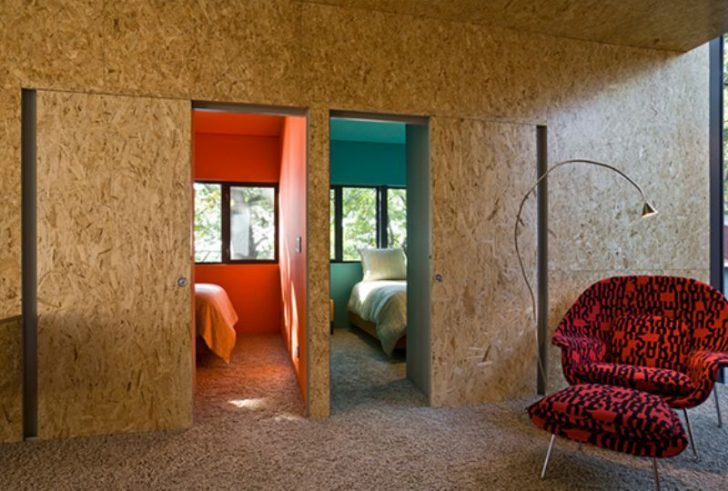

OSB boards have a special production method, which provides for the cross-arrangement of chip layers in the outer and inner layers, which makes them several times stronger than similar products made of MDF and chipboard. Despite this powerful slabs have excellent flexibility, which allows not only to wall the walls, but to give the room a completely new look, somewhere smoothing the corners, somewhere, on the contrary, creating sharp-angled ledges.

Decorating rooms with solid OSB panels

The non-standard structure of the OSB allows them to hold the screws well even when they are re-screwed into the existing hole. The material has excellent water resistance, which significantly expands the scope of its use. The most demanded OSB in the decoration of attics.

OSB slabs are popular in mansard trim

Oriented particle boards contain formaldehyde, so it is undesirable to decorate rooms where there is a lot of time, for example in the bedroom.

Very good for finishing log walls glass-magnesium sheet (SMP). Reinforcement with fiberglass improved the flexibility of the material and increased the permissible radius of curvature of the sheets to 3 meters. The risk that it will break or crack is minimal.

The glass-magnesium sheet has excellent flexibility

SMP light, fireproof, moisture resistant. They can not just finish the walls in a country house, but also use them to create interior partitions of different shapes. The front side of the sheet is prepared for painting, laminating, wallpapering, etc. It does not need to be puttyped and ground beforehand.

Block house

In appearance, the block house resembles an ordinary board, only with a convex cylindrical shape of the front side and non-standard processed ribs, which allow to quickly mount individual elements into a single web. Sheathing of this material will help maintain a unique microclimate inherent in wooden houses. On the interior finish take lamellas not thicker than 25mm. The lath is designed for their fastening.

Sheathing of walls in a wooden house by block house

Deciding to finish the country house block house, you need to remember that this material is always purchased with a 10% margin. Naturally, this is an additional cost, but having bought it in insufficient quantity, you risk ruining the decor of the whole room. The block house of different parties, like the wallpaper, differs in color shades, so it will be unreal to find an absolutely identical option purchased. Adding lamellas from another series will significantly reduce the aesthetic result.

Color scheme of the block house

The sheathing of the walls by the blockhouse looks great, but requires maintenance. In the process of its operation you will have to regularly clean the surface of the dust settling on it and update the varnish coating.

The laboriousness of the sheathing process itself can be attributed to drawbacks. Before you begin to equip the frame, you need to repair all the cracks in the wall of the log house and solve the problem of laying the heat insulation layer, which in combination becomes the absorber of the sound wave. But with such a “puff” finish the walls in the country house will always be warm and quiet. The sounds of the outside world will not disturb your peace.

Block-house mounting scheme

These small drawbacks of the block house are compensated by a whole list of advantages, among which:

- high-quality ventilation;

- simplicity of installation;

- strength;

- curative effect.

The sheathing of the walls by block house is distinguished by its strength

In addition, this kind of decoration can act as a link in the decor, combining in the finished composition, the beams and forging elements present in the interior, for example. The sheathing of the walls by block house is self-sufficient in an aesthetic sense and in itself, without additional inclusions, because it looks like a log-cut surface.

Sheathing of walls with block-house is self-sufficient

Sheathing of decorative stone

Actively to use a decorative stone in registration of interiors of country houses from a tree of steel not so long ago, though on their walls it also looks very interesting. His presence can set the tone for the whole situation. The most often they are made up of frame houses and structures made of laminated veneer lumber, but they rarely work with decorative stone in log buildings and rooms with rounded log walls. This is due to the fact that its plates require fixing exclusively on a flat surface.

Decorative stone in interior design of a wooden house

As for the quality of this sheathing, in addition to its high aesthetics, she is characterized by strength and practicality. It will last a very long time. Since the material is water resistant, it is acceptable to use it not only in the decoration of halls, living rooms and halls, but also in the design of bathrooms, kitchens, indoor pools and other premises of a house with high humidity.

Sheathing of walls in a wooden house with a durable decorative stone

Plastic in the decoration of the walls of a wooden house

Plastic is a practical and externally attractive material, which allows you to gently trim surfaces. It has an acceptable price. Basically, this kind of lining is used in wooden houses: in hallways, bathrooms, kitchen areas.

Cladding of bathroom walls with plastic panels

In addition to the fact that the plastic is moisture resistant, it is also very practical. To clean the surfaces of it, you do not need to use expensive abrasives. They can easily be put in order, simply wiping with a damp rag.

Plastic panels are easy to care for

Sheathing of plastic is not difficult to install. You can do it yourself, without recruiting specialists, which is also important for a limited budget.

Features of the plating of wooden walls in wet rooms

When making a room in a wooden house where a microclimate with a high humidity is expected, it is necessary to use only materials capable of resisting its impact on the wall covering. On those surfaces that are not directly in contact with water, you can use a moisture-resistant plasterboard or Quick Deck slab as a finishing. Those walls, where the water will fall often and in large volumes, it is better to hide behind plastic, plates of decorative stone or ceramic tiles.

Moisture-proof Quick Deck slabs

It is important to saddle the liner sealed so that the walls hidden behind it are not rotten and not blossomed from the water stains. Do not interfere with the preliminary treatment of their surface with moisture protection compounds. Particular attention in the decoration of the walls are given to the areas located behind the bathroom, toilet bowl, adjacent sinks.

When internal work begins on wall decoration

“It’s better not to rush and let the new building stay at least 10 months”

Finishing the house “fresh” log house can not begin before the shrinkage process is completed. For the structure of glued beams, this period lasts about four weeks, for the rest – stretches for many months. To calculate the time required to shrink a new house, you need to know the percentage of humidity used for construction of raw materials, the climatic features of the zone where the cottage is supplied, and take into account the duration of construction. In any case, it’s better not to hurry and let the new building stand at least 10 months. During this time, the logs themselves will dry up, and the heater, lying between the crowns, will die. Outwardly, it is difficult to notice the processes taking place, however, if you ignore the recommendations and cover the walls before the end of shrinkage, you can clearly see that it is quite active. Decoration necessarily twists, will cover the network of cracks, or even completely tear. In general, nothing will save you from the alteration, even the arrangement of the floating skeleton.

Conclusion

What and how to decorate the walls in your wooden house is up to you, but remember that you can count on a pleasant eye only if the process of decorating them is done correctly from the first steps.

Photo gallery – wall paneling in a wooden house

Video

Author: Mikhail Bond

05.05.2023 @ 19:12

d humid rooms, such as a bathroom or sauna. In such cases, it is better to choose a material that is resistant to moisture and mold.

In addition to wooden lining, there are other options for finishing the walls in a wooden house, such as various panels, block house, drywall, decorative stone, and plastic. Each of them has its own advantages and disadvantages, so it is important to carefully consider the characteristics of each material before making a choice.

Overall, the use of wood as a building material in a house creates a cozy and warm atmosphere, but it also requires special attention when it comes to finishing the walls. With the right approach and choice of materials, the walls in a wooden house can become a beautiful and functional element of the interior design.